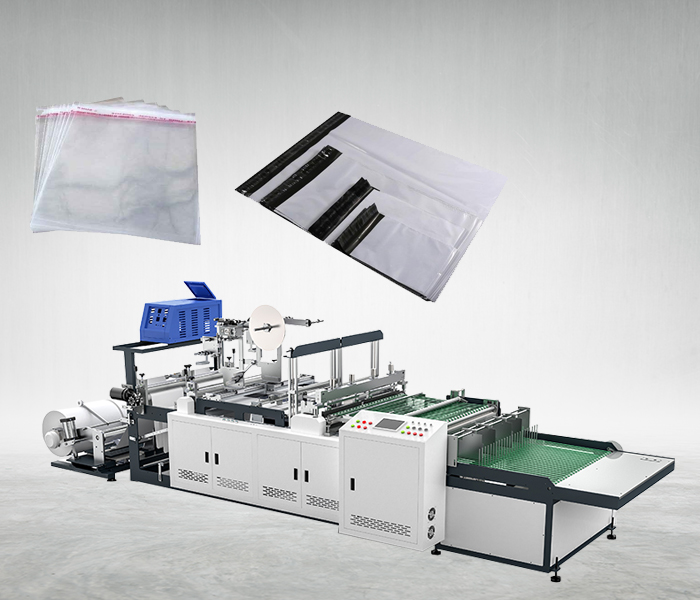

Courier Bag Maker Machine

Model Number : DBCB

Working Length : 75 - 650mm

Working width : 75 - 810mm

Mechanical Speed : 250 bags/min* (*depends on the material, thickness and sizes) In courier Bag: 80-100 bags/min* (*depends on the material, thickness and sizes)

Film Thickness

| Type of film & thickness |

Maximum |

Minimum |

| LDPE + LLDPE |

100 |

25 |

| HDPE- HM |

80 |

10 |

| PP |

75 |

25 |

| BOPP |

50 |

25 |

Quotation

| Sr. No. |

Description / Model |

| 1. |

DBE600SS COURIER Side Seal Bag Maker - ULTRA

Includes: Single pod sealer and VALCO MELTON glue unit + PLAIN BLADE FOR L.D |

Features of the Machine

-

Un-winder : Stand alone un-winder with Mechanical tension controller along with hydra pnumatic EDGE guide to maintain the film tension.

-

Film Folder : Special design folder with manual adjustable screw.

-

AC Servo Motor : AC servo motor for film index assisted tail – feed roller for better web tension control on attachment platform along with tail feed roller.

-

Draw Speed : Additional facility of draw speed to control speed of servo motor for film index makes application of variety of materials and process easy.

-

Different Types of Side Seal Blades : Different side seal blades can be offered running of different materials like low microns HDPE/P.P/Thicker microns HDPE/LDPE + LLDPE / Double seal Jobs.

-

Conveyor assembly : Bag pick-off roller is synchronized with movement of main sealing blade for efficient pick-off of bags after sealing, irrespective of bag size.

-

PID temperature controllers : PID temperature controller having auto-tuning feature, which ensures correct temperature on sealing jaw all the time. This function include in HMI.

-

Print registration : Photo cell alone with the machine to convert printed rolls.

-

Sturdy mechanical modular design : The machine has a sturdy structure of 12mm iron plates completely process on CNC laser cut.

-

Dancer assembly : Pivot Type Dancer assembly for film rolls unwinding speed control in the machine ensuing constant web tension while running of machine at any speed. Dancer is operated by air cylinder with tension setting with air pressure and speed control by linear potentiometer.

-

Operational : User friendly console for operator.

-

HMI : machine interface is 7” color wider and contain details of I/O, Attachments setting/ Errors/ Alarms for easy fault finding and operation. Whole machine moving parts are operating by timing belts and pulley to avoid maintenance and lubrication.

-

Guide Roll : All guide rollers are Aluminum thick pipe and anodized for long lasting.

-

Sealing Blade : Special design with uniform penetration throughout the width and OHNS special grade material for heating application.

-

Heater : High density cartridge heaters for better temperature maintain.

-

POD : silicon rubber roll is use For pod seal. With pneumatic CYLINDER are use to seal pod film.

-

GLUE UNIT : we are offering Valcomeltongule unit for courier bag maker.

TECHNICAL DETAIL

| Servo motor for Indexing |

1.0 KW |

| Tail feed Roller |

Additional Tail feed rubber roller to maintain film tension. |

| HMI |

7” Multicolor Touch screen |

| PLC |

1 Set |

| Photocell |

Data logic |

| Conveyor belts |

For pick up the bags |

| Main Motor |

2.0 HP 3phase AC Break Motor |

| Conveyor Motor |

1.0 HP 3phase AC Motor |

| Unwander Motor |

1.0 HP 3phase AC Motor |

| Air blow system instead of traditional springs system

|

| Anti-Static unit with 3 electrodes

|

| Side sealing Blade

| 1Sealer will Provided |

| Machine stops when the film exhausts (Makes may change sometimes) Stacking Table for collecting bags

|

Quick Inquiry